We are delighted to announce the recent acquisition of several major projects in the field of Continuous Emissions Monitoring (CEMS) and industrial process control.

AquaGas Pty Ltd, has been awarded a major contract for the supply, integration, installation and commissioning of two complete CEMS (Continuous Emission Monitoring System) used for compliance stack emissions monitoring of Prony Power Station located at one of the largest mining facilities located in southern hemisphere.

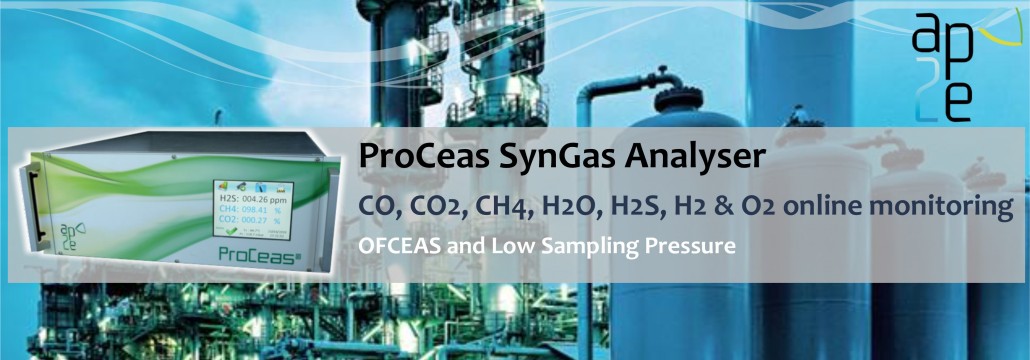

In this project, AquaGas has selected the LaserCEM (AP2E) and DR-320 R (DURAG) as the most suited technologies with regards to the application requirements and harsh monitoring conditions, providing the plant operator ENERCAL with the last generation of CEMS multigas analyser and dust monitors for online analysis of Particulates, HCl, SO2, NO, NO2, CO, CO2 and O2 at their two coal fired boiler facilities.

AquaGas scope also includes CDAS, Mcerts certified and state of the art data acquisition and reporting software suite. The CDAS software package ensures strict emissions reporting and clear environmental compliance.

The strong partnership with AP2E, expert in Laser Spectroscopy, and DURAG specialised in the field of environmental monitoring and process control has led to this first shared success, the acquisition of a capital reference for the LaserCEM in the field of power generation while enforcing AquaGas position in Oceania.

Prony Power Station is located on VALE mining site providing access to large port facilities for the supply of combustible. It consists of two 55 MW Alstom boilers (203 t/h – 87 bars – 515°C) equipped with Alstom turbines (85 bars – 500°C) and alternators (59 MVA – 11 kV) providing power for both the public demand and the needs of the large Nickel mining facilities.

Located close to the site and focused on customer satisfaction, AquaGas has implemented an efficient transfer of knowledge to the plant owner as well as to the local company ROBICAL assigned for the CEMS routine maintenance.

Continuous Emission Monitoring System

Caltex Lytton refinery in Australia

Caltex has recently approached AquaGas to perform a system expertise at their Lytton refining facilities near Brisbane.

The difficulties experienced by Caltex with their CEMS (Continuous Emission Monitoring System) had been related to the existing sampling method and resulted in a high maintenance level and unreliable monitoring operations.

Thanks to the customer feedback and following a couple of site visits, AquaGas has identified several ways to optimise the existing CEMS (Continuous Emission Monitoring System) sampling method. In order to secure the data availability and keep the maintenance requirements to their minimum, AquaGas Pty Ltd has supplied, integrated and installed a set of heated gas sampling probes:

Both the ASP300 and ASP400 provide the plant operator with application specific features and innovative design resulting in a series of advantages:

- Programmable back-flush sequences,

- Calibration as per CEMS code,

- Extended filtration surface,

- Flue gas temperature measurement

- Insitu filters – The ASP’s allows the inspection of the Insitu or “top filter” without the need for dismounting the probe (No fitters required for inspection or maintenance).

- Adjustable temperature set point (set at 190 degree Celsius)

- Continuous and automated soot removal performed directly at the sampling point

For further information on Ankersmid Gas Sampling probes, you can visit our website: www.aquagas.com.au.

CEMS integration made easy

Field proven, high quality, durable Ankersmid Sampling BVBA patented designs

Comprehensive range of gas sampling equipment from one source

Easy to install, maintain and operate

AquaGas is supporting the global industrial community with high performance environmental and process monitoring systems (Continuous Emissions Monitoring Systems, Air Quality Monitoring Systems, Online process analysers, Water Quality Monitoring Systems) specifically designed and built to meet your application requirements.