A new approach to continuous gas monitoring

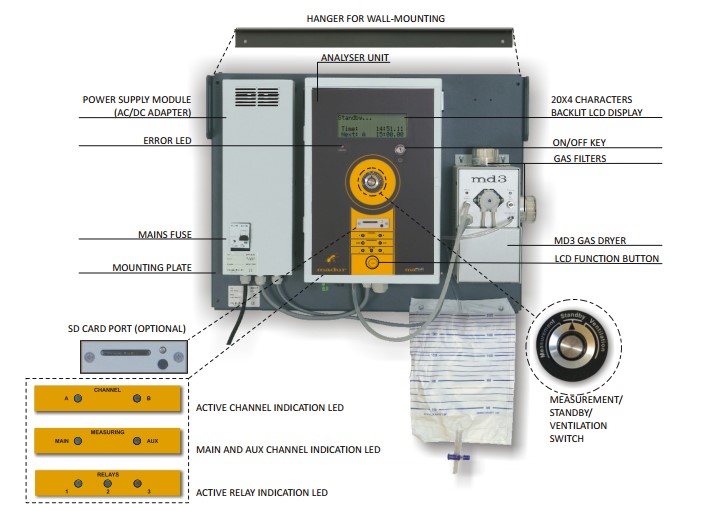

The Mamos is a high quality stationary monitoring system for the measurement of up to 6 gases as well as gas temperature, ambiant and differential pressures (Gas Flow) in a large field of applications.

Designed to optimise performance/price ratio, small in size and yet very skilful analyser, the Mamos is the field proven alternative for large, intricate Continuous Emissions Monitoring Systems, as it does not fall behind them concerning functionality, abilities, reliability and is far ahead in terms of expenses.

Online monitoring made easy

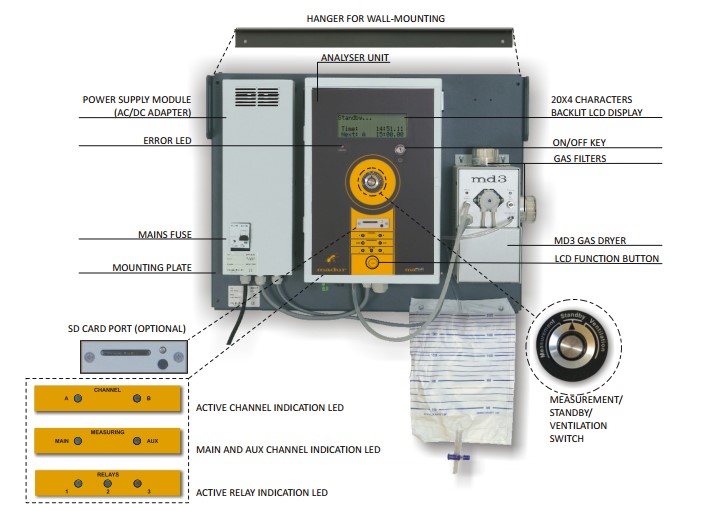

Fully automated and packed with exclusive features, the Mamos concept enlarges monitoring possibilities and respond to the today’s demands in terms of accuracy, reliability and flexibility. Each analyser is supplied with its own sampling system. The entire system is mounted on a wall mount plate and designed for installation in industrial settings and rough environment. It has a modular construction, and offer a large panel of add-ons to match site specific application requirements. The Mamos minimises the installation and ongoing operation cost until now required to fulfil your monitoring needs.

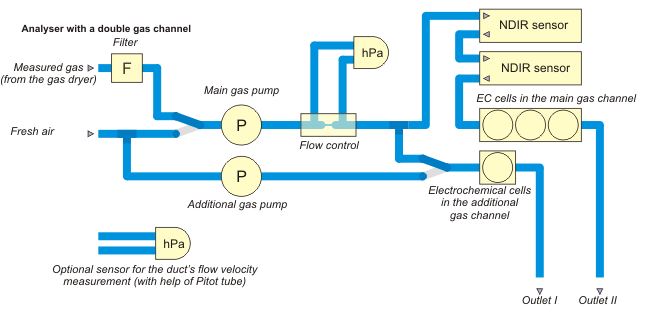

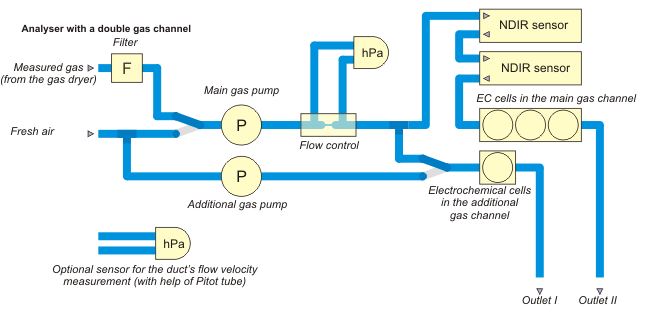

Depending of the gas matrix and components to be analysed, the Mamos can be fitted with up to 6 different sensors. The combination of technologies (NDIR, TCD, PID, Electrochemical) and the addition of separate gas channels into the same instrument empower flexibility in multigas applications. A unique feature is to allocate a gas channel to sensible sensors. Its design ensures the cells have a limited exposure to gases and therefore extends considerably their respective life-time.

Process gas and emissions monitoring in combustion plants, boilers, syngas, biogas, waste recycling facilities and associated filtration systems are typical applications for multiple gas channels configuration.

In Biogas, the primary gas channel holds the CO2, CH4, O2 sensors while an additional separate gas channel is allocated to sensible Electrochemical sensors, H2S for example. The two NDIR gas channels can then be used for CO and VOCs.

The Mamos offers multiple sensor and method configurations. Here are the measuring parameter for the most common gases. For other gases or different measuring ranges (MR), please consult us.

| Gas |

Analysis Method |

Range I Resolution |

Accuracy |

Time (T90) |

Conformity |

| O2

Oxygen

|

Electrochemical, Partial Pressure |

20.95% |

0.01%

|

± 0.1% abs. or 5% rel. |

45 sec |

ISO 12039,

CTM-030 |

| O2

Oxygen

|

Electrochemical, Partial Pressure |

25.00% |

0.01%

|

± 0.1% abs. or 5% rel. |

45 sec |

ISO 12039,

CTM-030 |

| O2

Oxygen

|

Electrochemical, Partial Pressure |

100.00% |

0.01%

|

± 0.1% abs. or 5% rel. |

45 sec |

ISO 12039,

CTM-030 |

| CO

Carbon Monoxide

|

Electrochemical Sensor |

4 000ppm |

1ppm

|

± 5ppm abs. or 5% rel. |

45 sec |

ISO 12039,

CTM-030 |

| CO

Carbon Monoxide

|

Electrochemical, with H2 compensation |

4 000ppm |

1ppm

|

± 5ppm abs. or 5% rel. |

45 sec |

ISO 12039,

CTM-030 |

| CO

Carbon Monoxide

|

Electrochemical Sensor |

20 000ppm |

1ppm

|

± 5ppm abs. or 5% rel. |

45 sec |

ISO 12039,

CTM-030 |

| CO

Carbon Monoxide

|

Electrochemical, with H2 compensation |

20 000ppm |

1ppm

|

± 5ppm abs. or 5% rel. |

45 sec |

ISO 12039,

CTM-030 |

| CO

Carbon Monoxide

|

Electrochemical Sensor |

10% |

0.001%

|

± 0.005% abs. or 5% rel. |

45 sec |

ISO 12039,

CTM-030 |

| CO

Carbon Monoxide

|

NDIR

Non Dispersive Infra Red

|

10% |

0.01%

|

± 0.05% abs. or 5% rel. |

45 sec |

EN 15058 and

Method 10

|

| CO

Carbon Monoxide

|

NDIR

Non Dispersive Infra Red

|

25% |

0.01%

|

± 0.05% abs. or 5% rel. |

45 sec |

EN 15058 and

Method 10

|

| CO

Carbon Monoxide

|

NDIR

Non Dispersive Infra Red

|

50% |

0.01%

|

± 0.05% abs. or 5% rel. |

45 sec |

EN 15058 and

Method 10

|

| CO

Carbon Monoxide

|

NDIR

Non Dispersive Infra Red

|

100% |

0.1%

|

± 0.5% abs. or 5% rel. |

45 sec |

EN 15058 and

Method 10

|

| CO2

Carbon Dioxide

|

NDIR

Non Dispersive Infra Red

|

5% |

0.01%

|

± 0.05% abs. or 5% rel. |

45 sec |

ISO 12039,

OTM-13

|

| CO2

Carbon Dioxide

|

NDIR

Non Dispersive Infra Red

|

10% |

0.01%

|

± 0.05% abs. or 5% rel. |

45 sec |

ISO 12039,

OTM-13

|

| CO2

Carbon Dioxide

|

NDIR

Non Dispersive Infra Red

|

25% |

0.01%

|

± 0.05% abs. or 5% rel. |

45 sec |

ISO 12039,

OTM-13

|

| CO2

Carbon Dioxide

|

NDIR

Non Dispersive Infra Red

|

50% |

0.01%

|

± 0.05% abs. or 5% rel. |

45 sec |

ISO 12039,

OTM-13

|

| CO2

Carbon Dioxide

|

NDIR

Non Dispersive Infra Red

|

100% |

0.1%

|

± 0.5% abs. or 5% rel. |

45 sec |

ISO 12039,

OTM-13

|

| CxHy

Total Hydrocarbons

|

NDIR

Non Dispersive Infra Red

|

1% |

0.01%

|

± 0.05% abs. or 5% rel. |

45 sec |

|

| CxHy

Total Hydrocarbons

|

NDIR

Non Dispersive Infra Red

|

5% |

0.01%

|

± 0.05% abs. or 5% rel. |

45 sec |

|

| CxHy

Total Hydrocarbons

|

NDIR

Non Dispersive Infra Red

|

10% |

0.01%

|

± 0.05% abs. or 5% rel. |

45 sec |

|

| CxHy

Total Hydrocarbons

|

NDIR

Non Dispersive Infra Red

|

25% |

0.01%

|

± 0.05% abs. or 5% rel. |

45 sec |

|

| CxHy

Total Hydrocarbons

|

NDIR

Non Dispersive Infra Red

|

50% |

0.01%

|

± 0.05% abs. or 5% rel. |

45 sec |

|

| CxHy

Total Hydrocarbons

|

NDIR

Non Dispersive Infra Red

|

100% |

0.1%

|

± 0.5% abs. or 5% rel. |

45 sec |

|

| NO

Nitric Oxide

|

Electrochemical Sensor |

1 000ppm |

1ppm

|

± 5ppm abs. or 5% rel. |

45 sec |

CTM-022 |

| NO

Nitric Oxide

|

Electrochemical Sensor |

5 000ppm |

1ppm

|

± 5ppm abs. or 5% rel. |

45 sec |

CTM-022 |

| NO2

Nitrogen Dioxide

|

Electrochemical Sensor |

1 000ppm |

1ppm

|

± 5ppm abs. or 5% rel. |

60 sec |

CTM-022 |

| NO2

Nitrogen Dioxide

|

Electrochemical Sensor |

4 000ppm |

1ppm

|

± 5ppm abs. or 5% rel. |

60 sec |

CTM-022 |

| SO2

Sulphur Dioxide

|

Electrochemical Sensor |

2 000ppm |

1ppm

|

± 5ppm abs. or 5% rel. |

45 sec |

|

| SO2

Sulphur Dioxide

|

Electrochemical Sensor |

5 000ppm |

1ppm

|

± 5ppm abs. or 5% rel. |

45 sec |

|

| H2S

Hydrogen sulfide

|

Electrochemical Sensor |

1 000ppm |

1ppm

|

± 5ppm abs. or 5% rel. |

70 sec |

|

| H2S

Hydrogen sulfide

|

Electrochemical Sensor |

10 000ppm |

1ppm

|

± 5ppm abs. or 5% rel. |

45 sec |

|

| H2

Hydrogen

|

Electrochemical Sensor |

2 000ppm |

1ppm

|

± 10ppm abs. or 5% rel. |

50 sec |

|

| H2

Hydrogen

|

Electrochemical Sensor |

20 000ppm |

1ppm

|

± 10ppm abs. or 5% rel. |

70 sec |

|

| H2

Hydrogen

|

TCD

Thermal Conductivity Detector

|

10% |

0.1%

|

± 0.5% abs. or 5% rel |

45 sec |

|

| H2

Hydrogen

|

TCD

Thermal Conductivity Detector

|

25% |

0.1%

|

± 0.5% abs. or 5% rel |

45 sec |

|

| H2

Hydrogen

|

TCD

Thermal Conductivity Detector

|

50% |

0.1%

|

± 0.5% abs. or 5% rel |

45 sec |

|

| H2

Hydrogen

|

TCD

Thermal Conductivity Detector

|

100% |

0.1%

|

± 0.5% abs. or 5% rel |

45 sec |

|

| N2O

Nitrous Oxide

|

NDIR

Non Dispersive Infra Red

|

2 000ppm |

1ppm

|

± 10ppm abs. or 5% rel |

45 sec |

ISO 21258 |

| N2O

Nitrous Oxide

|

NDIR

Non Dispersive Infra Red

|

5 000ppm |

1ppm

|

± 10ppm abs. or 5% rel |

45 sec |

ISO 21258 |

| CHF3

Fluoroform (Refrigerant R23)

|

NDIR

Non Dispersive Infra Red

|

2.5% |

0.01%

|

± 0.05 abs. or 5% rel. |

45 sec |

|

| CL2

Chlorine

|

Electrochemical Sensor |

250ppm |

1ppm

|

± 5ppm abs. or 5% rel. |

60 sec |

|

| VOC

Volatile Organic Compounds

|

PID

Photo Ionization Detector

|

100ppm |

1ppm

|

± 5ppm abs. or 5% rel. |

120 sec |

Method 21 |

| VOC

Volatile Organic Compounds

|

PID

Photo Ionization Detector

|

1000ppm |

1ppm

|

± 5ppm abs. or 5% rel. |

120 sec |

Method 21 |

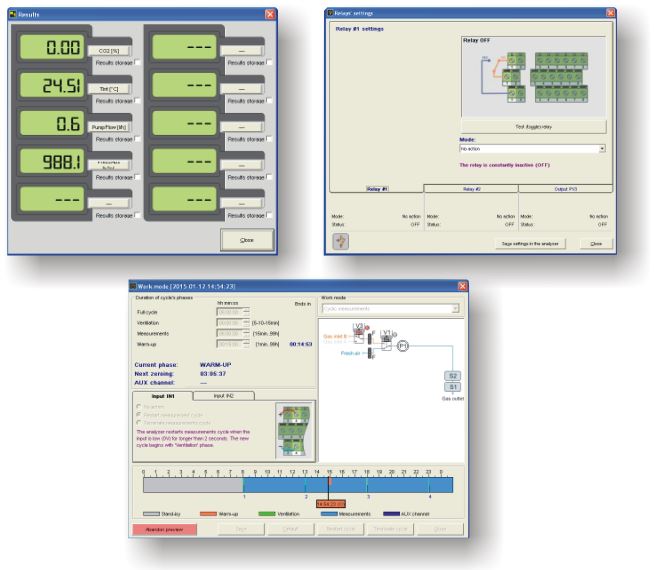

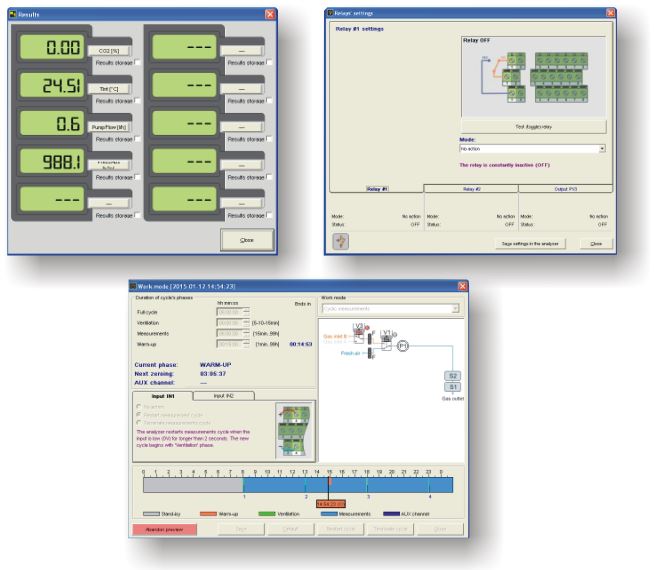

Its powerful and pleasant PC interface provides operators and system integrators with a broad range of settings to adjust many aspects of the measurement tasks such as automated sampling, calibration, purge sequences, analogue outputs behaviour, data presentations…

For large sites with complex monitoring requirements, the LAN and ModBus interfaces allow implementing in an efficient way large instruments networks with master/slave configurations and user settable monitoring functions.

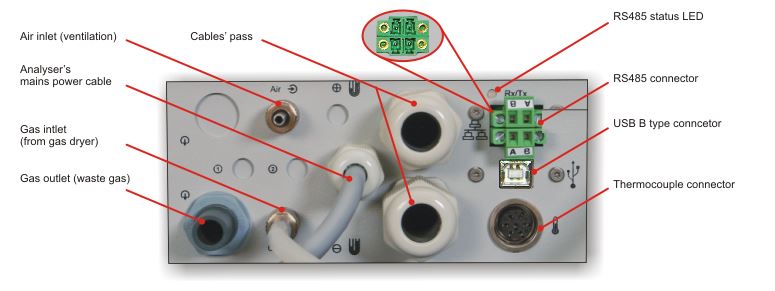

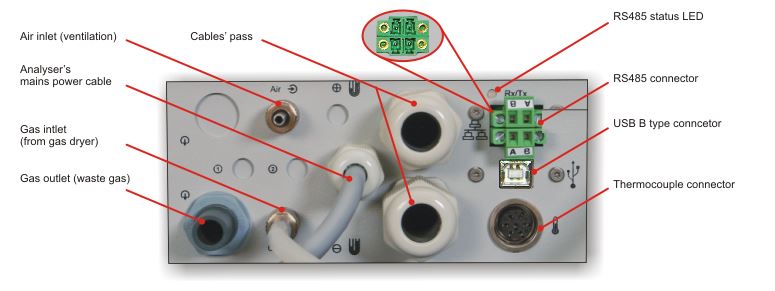

This compact system is delivered ready for installation. Thanks to its small size, the system is easy to locate, install and set-up. The routing of the cables and tubes to the instrument is simplified with all gas and electrical connections grouped onto a single plate.

- Miniature and field replaceable technology

- Standard configuration includes 6 sensors (NDIR, TCD, PID or Electrochemical)

- Measured gases: O2, CO, CO2, CxHy, NO, NO2, SO2, H2S, H2, N2O, Cl2, VOC

- Built-in real-time calculations for the following process parameters:

| Variable |

Method |

Range I Resolution |

Accuracy |

Response Time (T90) |

| Tgas

Gas temperature

|

K-type thermocouple |

-50 ÷ 1000°C |

0.1°C

|

± 2°C |

10 sec |

| Tgas

Gas temperature

|

S-type thermocouple |

-50 ÷ 1000°C |

0.1°C

|

± 2°C |

10 sec |

| Tamb

Boiler intake air temperature

|

PT500 resistive sensor |

-50 ÷ 1000°C |

0.1°C

|

± 2°C |

10 sec |

| DP

Differential Pressure

|

Silicon piezo-resistive pressure sensor |

25hPa ÷ +25hPa |

1Pa (0.01hPa)

|

± 2Pa abs. or 5% rel. |

10 sec |

| V

Gas velocity

|

With sampling probe equipped Pitot tube & pressure sensor |

1 ÷ 50m/s |

0.1m/s

|

0.3m/s abs. or 5% rel. |

10 sec |

| Lambda λ

Excess air number

|

Calculated |

1 ÷ 10 |

0.01

|

± 5% rel. |

10 sec |

| qA

Stack loss

|

Calculated |

0 ÷ 100% |

0.1%

|

± 5% rel |

10 sec |

| Eta η

Combustion Efficiency

|

Calculated |

0 ÷ 120% |

0.1%

|

± 5% rel |

10 sec |

- Large display / User friendly menu

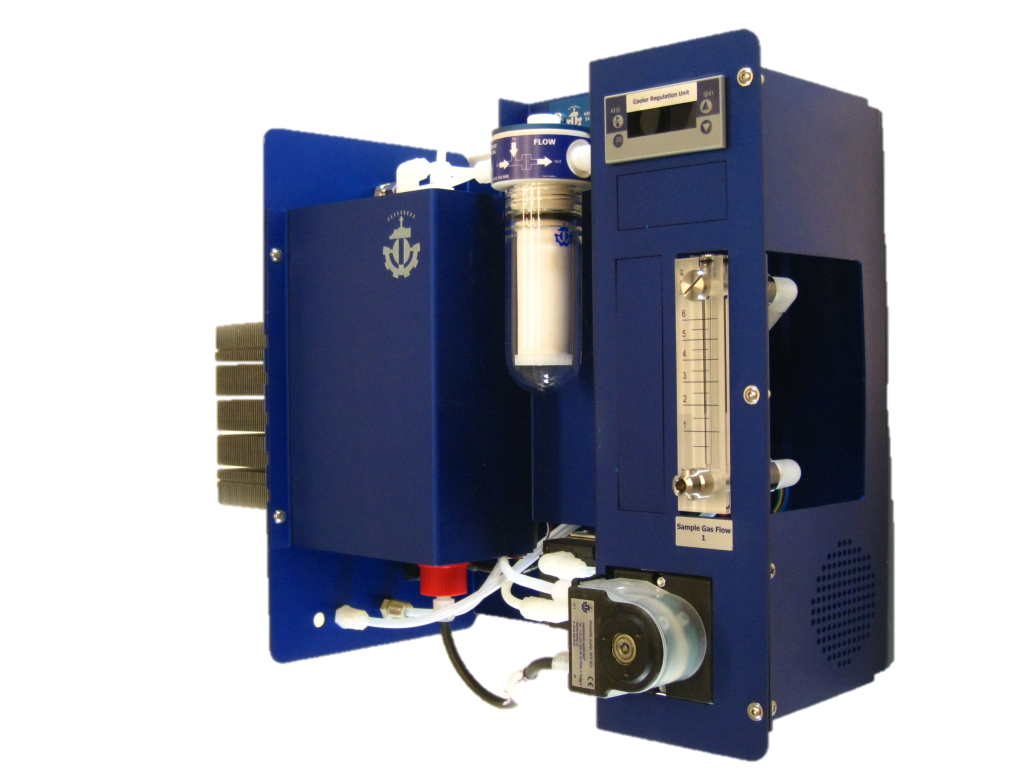

- Built-in gas chiller with continuous condensate removal

- Data-logger with SD card for results collection.

- Analogue outputs (both current and voltage) to control external devices

- User configurable functions controlled via digital and analogue inputs

- USB, LAN, RS485 and MODBUS

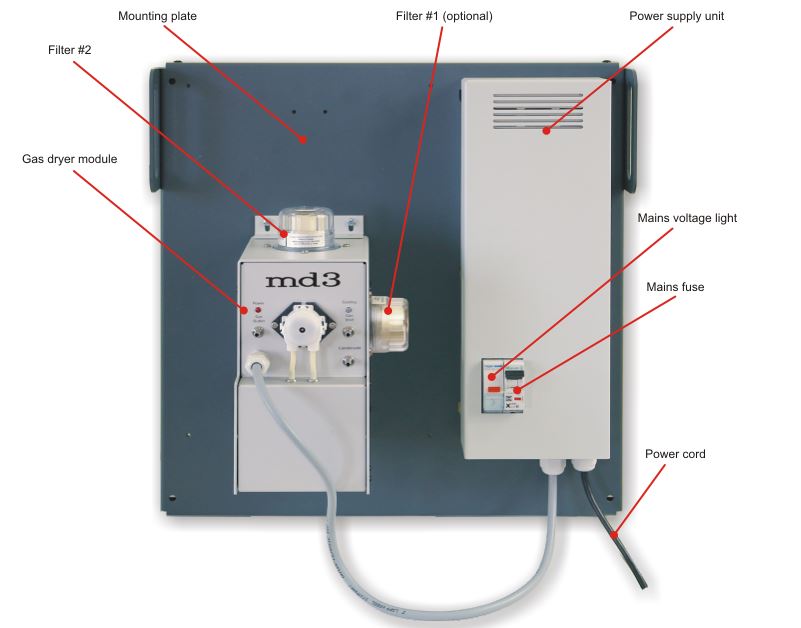

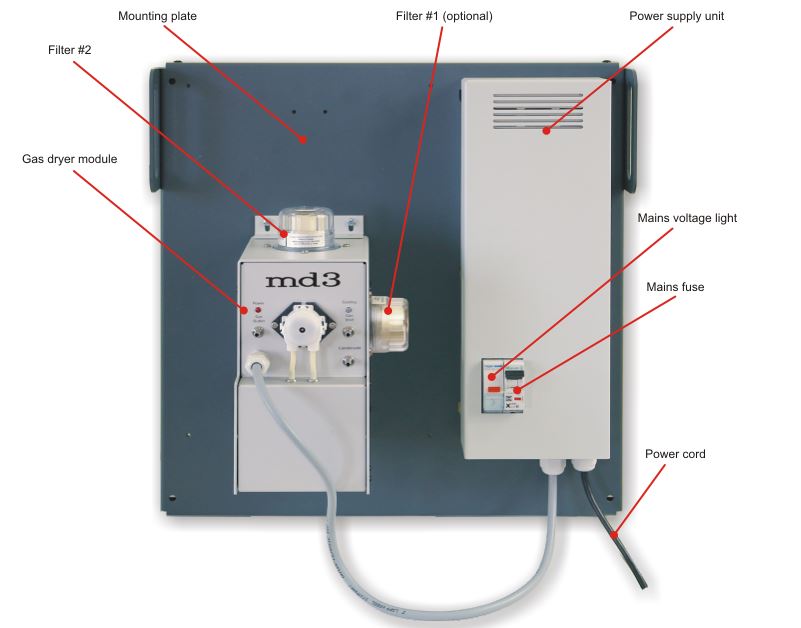

The sampling system configuration can be adapted to specific monitoring needs such as multipoint monitoring, redundancy, continuous or time set measuring cycles… When sampling from wet and hot gas, moisture content, condensates and salts are continuously removed by the use of one or several gas dryer(s) (Peltier or Nafion) equipped with built-in safety filter, condensate trap and safety inline particulate filters.

Wether it uses the built-in sampling pump or the pressure from the source, the analyser is designed to work with overpressure. Single gas channel configuration can handle overpressure up 1.8 bar.

MD3 for high moisture content – Waste incinerator, Syngas, Coal Power Stations, Chemical and refinery facilities, (…)

MD2 for low and medium moisture content – Biogas, landfill, odour filtration system, LNG, (…)

Compact – Short-extractive CEMS – Analyser with gas dryer on a common mounting plate, all installed near the measurement place.

| Dimensions (W x H x D) |

240 mm x 360 mm x 160 mm |

| Weight (depends on equipment) |

4 kg ÷ 5 kg |

| Casing’s material |

ABS |

| Protection grade |

IP 20 |

| Mounting plate

dimensions (H x W) | material | weight

|

596 mm x 450 mm | aluminium | 1.9 kg |

| Operating conditions |

T: 10°C ÷ 50°C, RH: 5% ÷ 90% (non-condensing) |

| Storing temperature |

0°C ÷ 55°C |

| Power consumption (analyser unit only) |

30 W max |

| Data-logger: type | size | number of results |

SD flash card | max 4GB | practically unlimited |

| Display: type | parameters |

Backlit LCD | 20 characters x 4 lines |

| Gas pump: type | max gas flow | standard gas flow |

Diaphragm | max 2l/min | 1.5l/min (90l/h) |

| Maximal extraction point pressure: |

Atmospheric ±200hPa |

| Current analogue outputs |

4 outputs 0mA ÷ 20mA or 4mA ÷ 20mA |

| Voltage analogue outputs |

4 outputs 0V ÷ 5V or 0V ÷ 10V |

| Digital inputs |

2 inputs, TTL levels, floating = high level |

| Digital outputs |

1 open collector output + 2 SPDT relays (optional) |

| Computer communication interface |

B type USB socket |

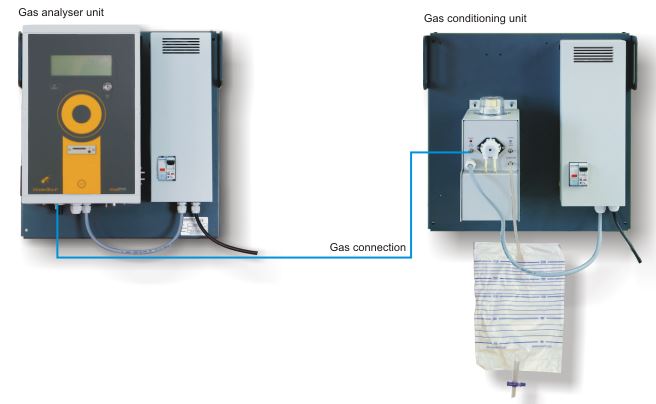

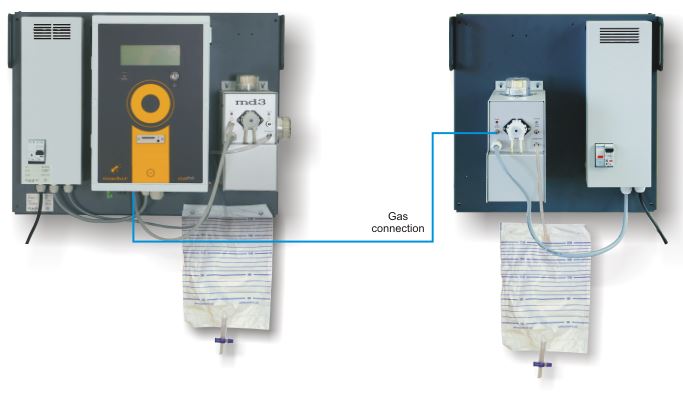

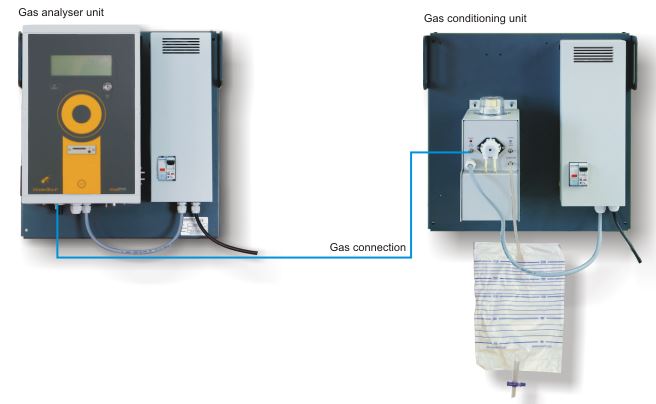

Split /1 dryer – Cold Dry Extractive CEMS – Analyser and gas dryer are installed on separate mounting plates, each equipped with its own power supply module. The gas dryer is installed near the sampling point therefore the analyser can be located away from the source. Once free from water vapour, the sample can be conveyed on long distances without the need for heated lines.

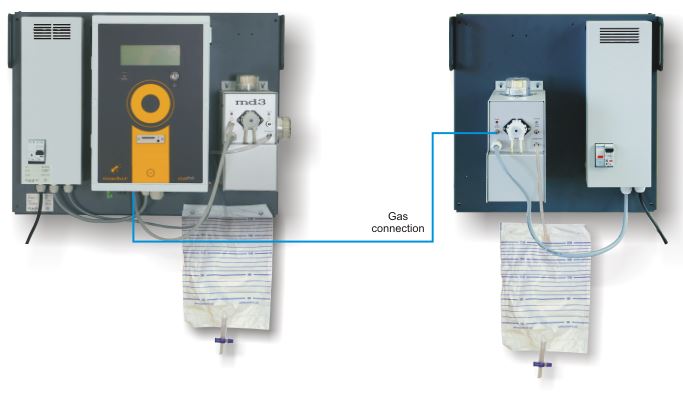

Split/2 dryers – Cold Dry Extractive CEMS – Compact configuration with an additional gas dryer installed on separate mounting plates, each equipped with its own power supply module. Two dryers in serial for high drying performances suitable for Traces monitoring in wet sample.

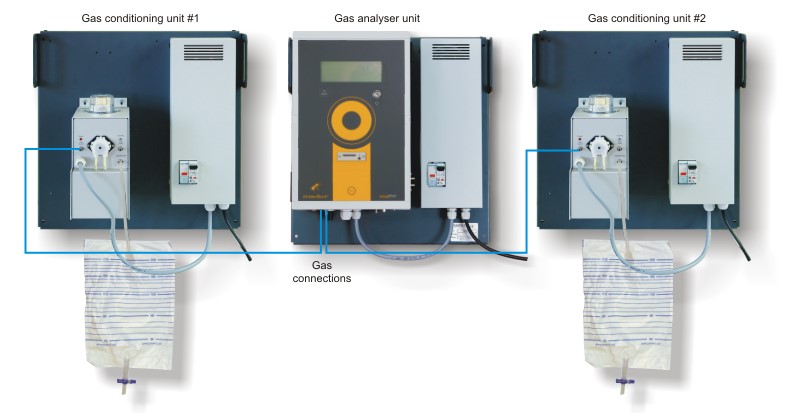

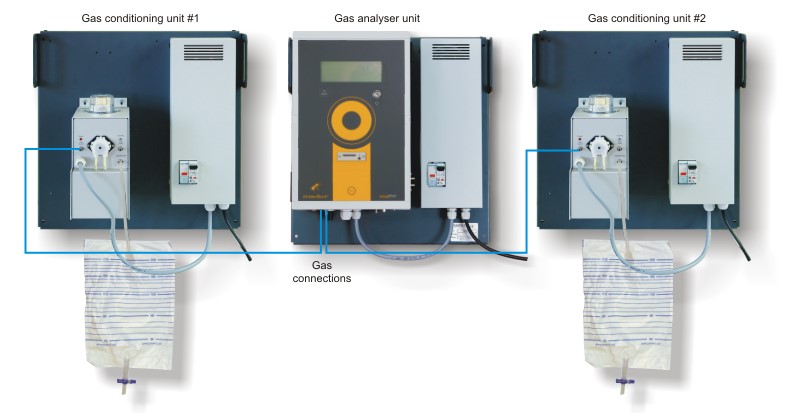

Twin Split – Cold Dry Multipoint CEMS – This version is based on the Twin Split/1 dryer configuration, but uses two MD3 dryer with their own power supply added on separate mounting plates enabling measurements from two different locations (each dryer is installed near the sampling point). User programmable sampling sequences.

-

-

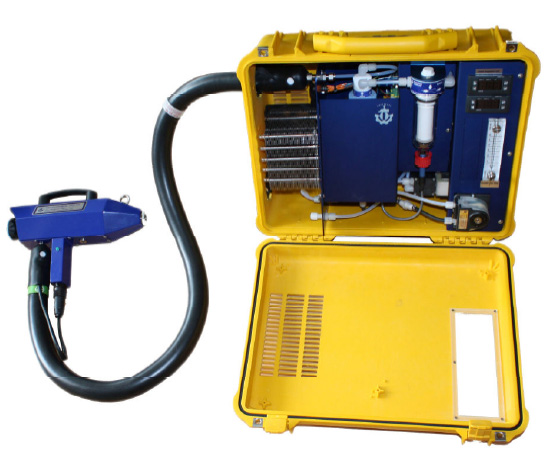

Portable Gas Analyser

-

-

PGD100 – Gas Conditionner

-

-

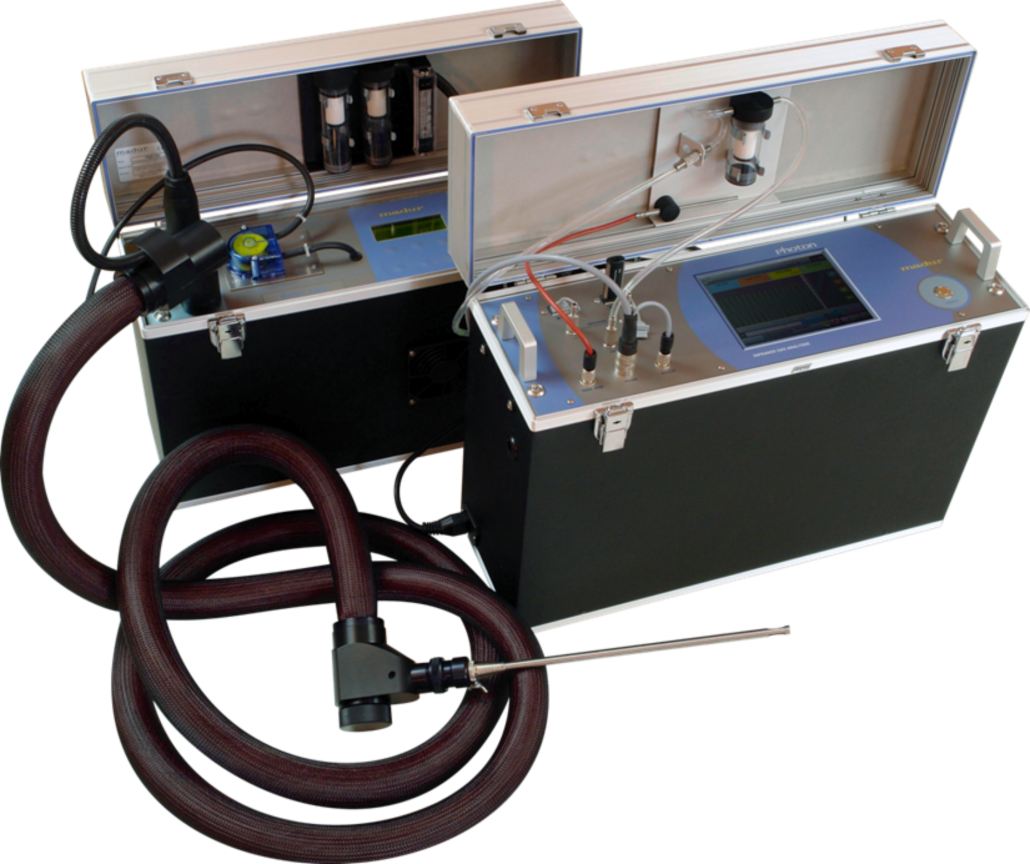

GA21plus – Portable Gas Analyser

-

-

Hand held Analyser

-

-

PhotonS – Stationary CEMS

-

-

MD3 Gas dryer

-

-

Portable Gas Analyser

-

-

GA12 – Handheld Analyser

-

-

Portable Gas Analyser

-

-

Low Cost multigas CEMS

-

-

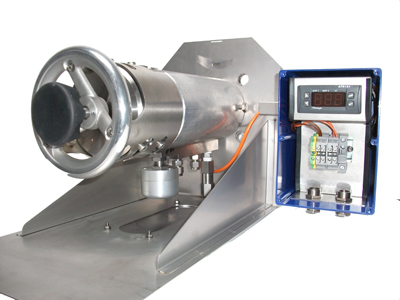

Stationary Gas Sampling Probes

Call us with your application details handy to organise a CEMS demo at your facilities !

AquaGas is supporting the global industrial community with high performance environmental and process monitoring systems (Continuous Emissions Monitoring Systems, Air Quality Monitoring Systems, Online process analysers, Water Quality Monitoring Systems) specifically designed and built to meet your application requirements.