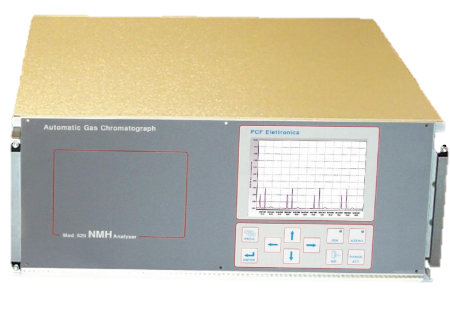

The 529H® FID detector is a carbon atom counter. A sample is introduced into a micro flame lit by hydrogen and air (1:10 ratio), where the electrical charges generated by the oxidation of Cx to CO are proportional carbon content in the sample. The electrical charges are collected by two polarised electrodes and converted by an electrical circuit into an electronic signal. The PCF’s Mod. 529 NMHC (Non Methane Hydrocarbon) gas chromatographic analyser is intended for continuous monitoring of Total Hydrocarbons (THC) and the methane (CH4) fraction in ambient air (529®) and stack emissions (529H®).

| Combination of GC and FID methods for Online monitoring of THC, CH4 and NMHC | Proprietary micro FID detector |

| Keyboard / LCD display interface for configuration & calibration | Built-in automatic ignition |

| Modular and universal high performance associated gas sampling system | Fully automatic standalone system for fast, accurate and reliable analysis of THC, CH4 and NMHC |

| GAS | FULL RANGE | LoD |

|---|---|---|

| THC | 10 to 500 ppm | 0.02 ppm |

| CH4 | 10 to 500 ppm | 0.02 ppm |

| NMHC | 10 to 500 ppm | 0.02 ppm |

The separation of methane fraction is based on the chromatographic method. Once specified the CH4 is measured separately and then subtracted from Total Hydrocarbons concentrations. The measuring sequences are managed by the built-in 10 port rotation valves enabling sequential measurement of THC, CH4 and NMHC. A zero calibration cycle triggered automatically before each measuring cycle guarantees a high signal stability and efficient drift compensation.

The same technology can be adapted to specific VOCs stack emissions monitoring and process control needs. The coupling of gas chromatography separation with state of the art FID detector allows accurate and reliable measurement of Benzene (C6H6), Ethylene (C2H4), Propylene (C3H6), Styrene (C8H8), Acetone (C3H6O), Formaldehyde (CH2O) and many others VOCs.

| GAS | FULL RANGE | LoD | ACCURACY |

|---|---|---|---|

| Benzene C6H6 | 0-10 / 0-20 / 0-50 / 0-100 /0-200 / 0-500 ppm | 0.05 ppm | 1% full scale |

| Ethylene /Ethylene Oxide (ETO) C2H4 | 0-10 / 0-20 / 0-50 / 0-100 /0-200 / 0-500 ppm | 0.02 ppm | 1% full scale |

| Propylene / Propylene Oxide C3H6 | 0-10 / 0-20 / 0-50 / 0-100 /0-200 / 0-500 ppm | 0.02 ppm | 1% full scale |

| Styrene C8H8 | 0-10 / 0-20 / 0-50 / 0-100 /0-200 / 0-500 ppm | 0.5 ppm | 1% full scale |

| Acetone CH36O | 0-10 / 0-20 / 0-50 / 0-100 /0-200 / 0-500 ppm | 0.5 ppm | 1% full scale |

| Formaldehyde CH2O | 0-10 / 0-20 / 0-50 / 0-100 /0-200 / 0-500 ppm | 0.1 ppm | 1% full scale |

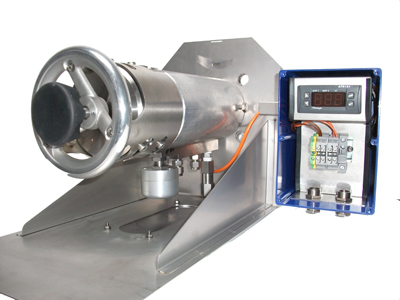

Available in different lengths, the ASP series suits a wide range of sampling requirements in terms of temperatures and dust loads. Thanks to its modular conception and large selection of options, the ASP series enable efficient system integration and reliable long-term operations. The probe temperature (user programmable 0-200°C) is controlled by a microprocessor based PID-controller and a built-in temperature sensor. Alarm Threshold, Temperature set point and fault contacts can be programmed according to the application requirements. The standard sensor is PT100, whereas a thermocouple is standard for the high temperature version. A significant advantage is that all filters are replaceable without without dismounting the probe assembly from the flanges without using any tools. Cleaning and exchanging of unheated sample tubes or preliminary top-filters can be performed by extracting the filter and sample tube from the probe barrel in the shortest possible time.

The AHL electrically heated sample lines series is designed for connecting to all type of sampling equipment. The use of heated line ensures that the gas components in the sample stream remain above their respective dew point and thereby eliminates the risk of condensation. Thanks to a modular design and a large selection and combination of options, the heated lines AHL ensures safe and reliable sample transfer within CEMS or process monitoring systems. The ATEX heated sample lines series AHLX are designed to transport sample gas through explosive zone type 1 or 2.

Fast Loop sampling system have a significantly higher accuracy than standard FID inline analysers. They were developed in response to demands for a fast online VOCs and THCs extractive monitoring systems that incurs no pressure drop in the main process. The Fast Loop system extracts a representative stream from the process line using a AMP 510 Heated Sampling Pump. The AMP 510 ensures representative and fast transfer of the sample to the 529H® -Online FID Analyser.

- Oil free operation – no contamination of the media

- Heavy duty / low maintenance

- Temperature controlled 0 to 180 degree C

- Gas tight Leakage < 6 x 10-3 mbar l/s

Ankersmid ATEX certified Sampling System components can be installed in explosive areas (Zoning: II2G EEx d e ib IIC T3, II3G, Ex nR IIB T3, Ex II 3G Ex ma IIA T3, Ex II 3D Ex ma IIIB and more). The ATEX Sampling System product range offers Ex proof rated site specific options with Exd-temperature sensor type Pt100, controlled by an ATEX-certified controller-limiter unit. The sampling system components are delivered with valid ATEX-certificates for all electrical components and available with various filter element lengths and materials.

529H® – THC, NMHC and CH4 Online Monitoring

Typical Applications

Process gas and emissions monitoring in combustion plants, boilers, syngas, biogas, waste recycling facilities (Waste to Energy) and associated filtration systems are typical applications for the 529H® – THC, NMHC and CH4 online FID analyser.

Landfills, Biogas Plants, Incinerators

“Landfilling” is the main method for disposal of municipal and household solid wastes or refuses in Australia. Although maintained in an oxygen-free environment and relatively dry conditions, landfill waste produces significant amounts of landfill gas (mostly methane). The 529H® FID enables process and air pollution emissions monitoring from solid waste landfills. Landfills operations require the control of methane CH4 and non-methane organic compound emissions (NMHC) emitted.

- THC, NMHC and CH4 measured during the methanation process give a good overall view of the performance of the degradation process and bacterial activity. A decrease in methane content can be a first sign of organic overload, provided that the feedstock mix has not recently changed.

- Simultaneous real-time monitoring of THC, NMHC and CH4 empowers process automation (i.e. operation of scrubbers).

- THC, NMHC and CH4 Continuous Stack Emissions Monitoring required for environmental compliance

Thermal Oxidiser

Thermal oxidisers are typically used to eliminate HAPs and VOCs from industrial air streams . These pollutants are generally hydrocarbon based and when destroyed via thermal combustion they are chemically oxidized to form CO2 and H2O. The temperature needs to be high enough to ignite the waste gas. Most organic compounds ignite at the temperature between 590°C and 650°C. Accuracy and high reliability in harsh conditions of operations makes the 529H® – THC, NMHC and CH4 a powerful optimisation tool for thermal oxidisers. GTC and thermal oxidisers reduce the emissions of pollutants such as Volatile Organic Compounds (VOC). Online monitoring of THC, NMHC and CH4 upstream of the Thermal Oxidiser enables optimal process optimisation.