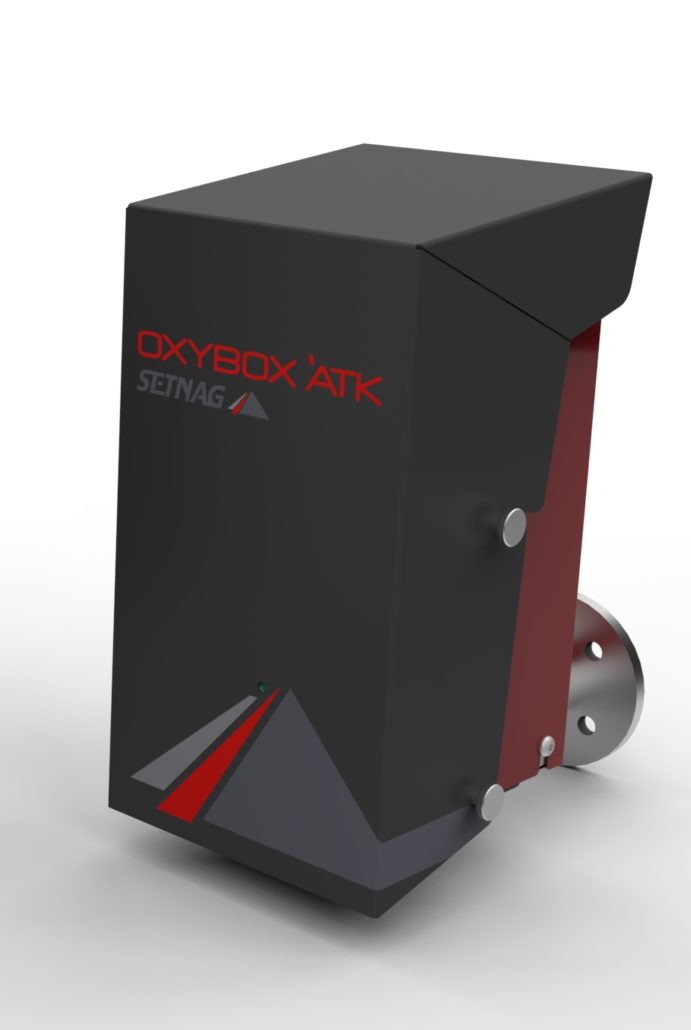

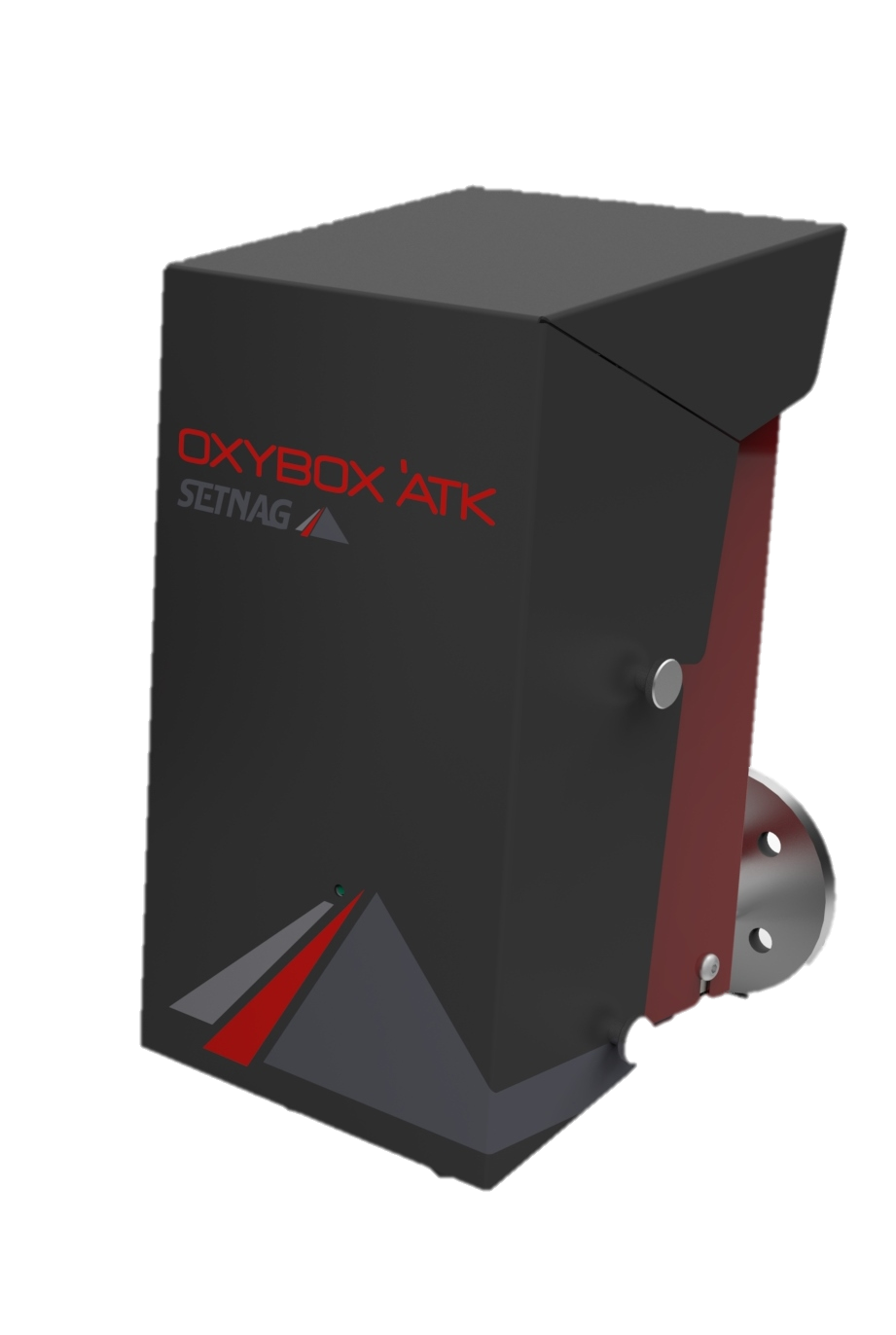

| No need for reference gas: use of the MicroPoas® | Pump Free System |

| Maximum gas temperature: up to 1300° C continuously, depending on the version | “Removable” probe tubes: easy to dismantle and replace for simple and cost-effective maintenance. |

| No sensitive parts and no hot spot inside the duct | Limited maintenance and service operations: easy probe tube cleaning with compressed air and/or fast dismantling. |

| GAS | RANGE | Accuracy |

|---|---|---|

| O2 | Combustion 0.01 to 25 % | 2% MR |

| COe | 0-10,000 ppm | 2% MR |

| Partial Pressure | 10-35 to 0.25 atm O2 | 2 % relative |

Response time T90 < 35 s.

QAL1 COMPLIANT (EN14181)

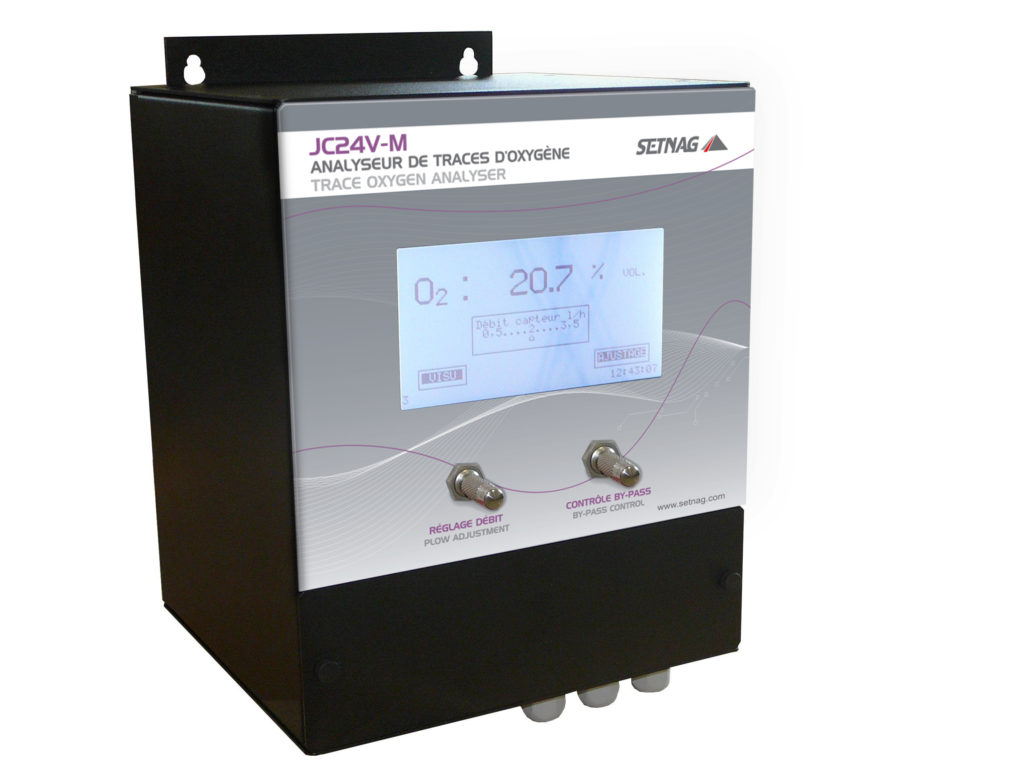

JC24V trace oxygen analysers – designed and manufactured by SETNAG – meet the requirements of industrial gas production and heat treatment industries. It includes the unique technology designed by SETNAG: the MicroPoas®, zirconia sensor with built-in metallic reference. SETNAG is ISO9001 accredited since 2000. This standard guarantees its involvement for its customers total satisfaction

• MicroPoas® technology • Configuration via USB • 230VAC or 24VDC • For gas temperature up to 600C

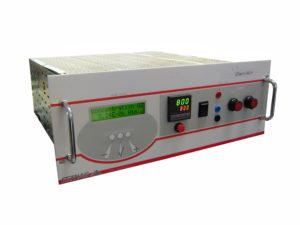

The S24N-2020 is perfectly suited to extractive CEMS applications and can be operated either in wet gas (heated line required) or in dry gas.

MicroPoas® technology • Suited to extractive CEMS • Gas temperature up to 600®c • Easy to integrate and operate • Rack mount enclosure • Low maintenance • Extremely high reliability

Oxygen measurement on wet gas (direct connection at heated hose outlet)

Oxygen measurement on dry gas (after sample conditioning)

SETNAG O2 analyser application range

Industrial Gas Manufacturer

Trace Oxygen monitoring

JC 24V online analysers series of trace Oxygen in pure and inert gases meets the requirements of industrial gas manufacturers, heat treatment engineering, controlled atmosphere, air separation, control of particular atmospheres, tightness control, gas inerting processes and more…

Combustion Control

Continuous Emissions Monitoring

In coal and gas fired power stations, cement kiln, foundry, paper mills… Stringent regulatory requirements for emission monitoring and reporting. The SETNAG Oxygen Analysers enables efficient and flawlessly compliance for a large range of contaminants.

SETNAG’s oxygen analysers and other flagship products find applications in numerous fields such as industrial processes. The products are well recognized for their high technology, their efficiency, rigor and long life span.

Continuous Emissions Monitoring

SETNAG’s oxygen analysers and other flagship products find applications in numerous fields such as energy and incineration. The products are well recognized for their high technology, efficiency, accuracy and long life span.

– Power generation

– Steam production

– Food processing industry

– District heating

– Biomass power plant

– Incineration of domestic and industrial waste

Research and Safety

Continuous measurement of the generated atmosphere between 10-35 and 0.25atm

Use of different kinds of carrier gases, at various concentrations

Limited costs as a single gas is required

Very high measurement accuracy: use of the MicroPoas®

Low gas consumption: necessary flow 1 to 13 l/h

Control of the applied voltage and current

Maintenance-free

MEASUREMENT TECHNIQUE

The oxygen pump set uses the principle of ionic conduction of zirconia. When a continuous voltage is applied across the zirconia tube terminals an oxygen flow is created. The quantity of oxygen in the gas circulating inside the zirconia tube will increase, or decrease, according to how the voltage is applied.

The partial pressure is measured by the MicroPoas™.