Gas conditioning and sampling equipment for various applications, including environmental monitoring, industrial processes, and research laboratories. The products include gas sampling probes, sample conditioning systems, and diluters that are designed to ensure accurate and reliable measurements of gas concentrations.

DLD

Calibration gas diluter | Gas conditioning and sampling

DLD series diluters are designed to dilute calibration gas for verifying the calibration lines of fixed or portable gas analyzers. These diluters are available in versions with 2 or 3 inputs, each with a specific range. Gas flow measurements are performed using mass flow sensors, and the results are displayed on the device. Once the cylinder concentrations are inputted, the DLD calculates and displays the dilution percentage of the reference gas. Users can also directly control individual mass flows, and each flow can be calibrated using its own metrological chain.

In addition to lab use, the DLD2 and DLD3 are also suitable for field applications, as they come in a durable and shockproof case.

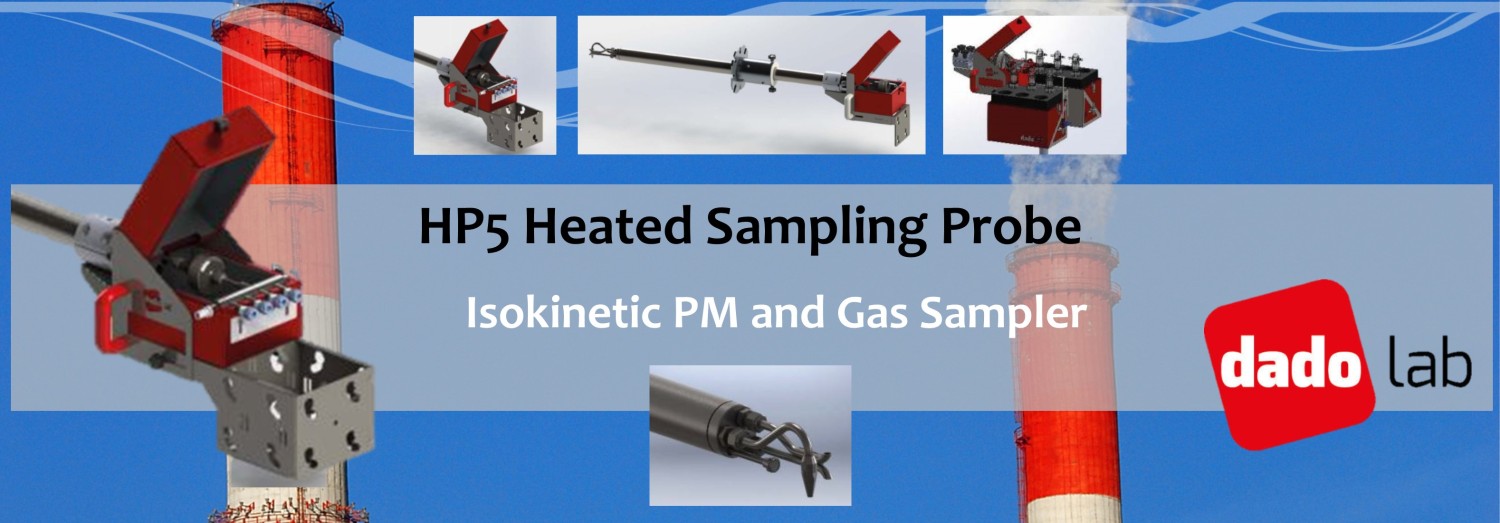

Meets and exceeds the requirements of European Union regulations and meets international quality standards:

-

- PM10 and PM2.5 (ISO23210 VDI2066/10)

- HCl (EN1911, EPA50, EPA51)

- Dust (EN 13 284-1 and EPA5)

- Heavy metals (EN14385 and EPA 60)

- Insitu Velocity and Flow rate determination in accordance with EN 16911-1 and EN 15259

MAIN FEATURES

| Gas Dilution: The DLD3 dilutes calibration gas to verify calibration lines of fixed or portable instrumentation, with a range from 10:1 to 100:1 for each input. | Mass Flow Sensors: The diluter uses three mass flow sensors to measure gas flows with high accuracy and reliability. |

| User Control: The DLD3 allows users to directly control each mass flow and adjust the dilution percentage of the reference gas. | Calibration: Each mass flow sensor can be calibrated independently, with traceability to the international standard. |

| Compatibility: The DLD3 is compatible with various calibration gases and gas analyzers, including those with low flow rates. | Display: The diluter features a display that shows gas flow rates, dilution percentage, and other information in real-time. |

| Portability: The DLD3 comes in a rugged, shockproof case, making it suitable for both laboratory and field use. | Safety: The diluter is equipped with safety features, including overpressure protection and gas leak detection. |

HP1

VOCs Probe | Gas conditioning and sampling

The HP1 probe represents a step forward from the previous MDG Probe, designed to function in conjunction with FID instruments. The HP1 is more compact, lightweight, and user-friendly than its predecessor.

The HP1 probe is offered in four variants:

HP1-1W, with one outlet for a heated line

HP1-1WT, the same as above, but with thermoregulation

HP1-2W, with two outlets for two heated lines

HP1-2WT, the same as above, but with thermoregulation

The 2W version enables two analyzers or two sampling lines to be connected concurrently.

The HP1 probe is equipped with 220V self-regulating elements built-in, with a set-point of 180°C +/- 15° hysteresis. The thermoregulated version facilitates connection to a heated tube, and the temperature can be set on the thermoregulation unit.

An LED indicator notifies when the temperature set-point is reached.

The connections are Swagelok and made of steel with a diameter of 6mm or 8 mm upon request, carefully selected to endure long and sustained heat exposure.

Meets and exceeds the requirements of EN 12619, dilution samplers or automatic measuring systems:

-

- PM10 and PM2.5 (ISO23210 VDI2066/10)

- HCl (EN1911, EPA50, EPA51)

- Dust (EN 13 284-1 and EPA5)

- Heavy metals (EN14385 and EPA 60)

- Insitu Velocity and Flow rate determination in accordance with EN 16911-1 and EN 15259

MAIN FEATURES

| Compatibility: The HP1 probe is designed to work with FID instruments in accordance with EN 12619, dilution samplers, or automatic measuring systems. | Compact Design: The HP1 is smaller and lighter than its predecessor, making it more practical and easier to use. |

| Multiple Versions: The HP1 is available in four versions, with different configurations of outlets and thermoregulation. | Heating Elements: The probe is equipped with 220V self-regulating heating elements with a set-point of 180°C +/- 15° hysteresis. |

| LED Indicator: The probe features an LED indicator that signals when the temperature set-point is reached. | Swagelok Connections: The connections are made with Swagelok fittings, available in steel with a diameter of 6mm or 8mm. |

| Durability: The connections and materials are specifically selected to resist long and continuous heat stress. | Versatility: The 2W version allows for the connection of two analyzers or two sampling lines simultaneously. |

GD1

Gas conditioning system | Gas conditioning and sampling

The GD1 gas conditioning system is designed for use with combustion analyzers and is specifically engineered to handle gas emissions. The system features a high-head pump capable of extracting samples even from chimneys with high depressions. The air conditioning system incorporates advanced protective systems to safeguard the analyzers.

Meets and exceeds the requirements of EN15058:2017 for gas temperatures:

-

- PM10 and PM2.5 (ISO23210 VDI2066/10)

- HCl (EN1911, EPA50, EPA51)

- Dust (EN 13 284-1 and EPA5)

- Heavy metals (EN14385 and EPA 60)

- Insitu Velocity and Flow rate determination in accordance with EN 16911-1 and EN 15259

MAIN FEATURES

| Compatibility: The GD1 is designed to work with combustion analyzers and is optimized for gas emissions. | High-head pump: The GD1 features a high-head pump capable of extracting samples even from chimneys with high depressions. |

| Temperature regulation: The air conditioning system is designed to meet the stringent standards for gas temperatures. | Protective systems: The GD1 is equipped with advanced protective systems to safeguard the analyzers. |

| Modular design: The system has a modular design, allowing for easy maintenance and customization. | Easy installation: The GD1 is simple and easy to install, with minimal requirements for set-up. |

| Durability: The materials and construction of the GD1 are designed for long-lasting durability and reliability. | Offers compatibility, a high-head pump, temperature regulation, protective systems, modular design, easy installation, and durability for use with combustion analyzers and gas emissions. |

TARGETED POLLUTANTS

POPs – persistent organic pollutants

POPs have been discovered to be the relevant part of emissions to the environment causing health effects, including dioxins (PCCD/F), polychlorinated biphenyls (PCBs), polyaromatic hydrocarbons (PAHs), hexachlorobenzene (HCB) and others. These compounds have a high stability, low volatility and are degraded very slowly. Due to the lipophilic character, an accumulation in the human body takes place.

Fine & Coarse dust

Fine dust is the portion of solids in gases being the focus of concern for pulmonary health effects. ParTrace® cartridges trace the fine dust fraction of general concern, PM10, PM2.5, PM1, and splits them in the respective fractions within one sampling run.

Volatile Organics Compounds

Odour indicator Components