Mine Water Online Analysers

The use of water in mining has the potential to affect the quality of surrounding surface water and groundwater. In response to environmental concerns and government regulations, the mining industry worldwide increasingly monitors water discharged from mine sites, and has implemented a number of management strategies to prevent water pollution. Water issues and management vary from site to site and must be addressed locally.

How mines use water

Mining operations use water for mineral processing and metal recovery, controlling dust, and meeting the needs of workers on site. The amount of water required by a mine varies depending on its size, the mineral being extracted, and the extraction process used. For instance, metal mines that chemically process ore to concentrate metals such as copper and gold use much more water than non-metal mines such as coal, salt, or gravel mines.

Although a large mining operation may use a considerable amount of water, the minerals industry overall consumes a relatively small quantity of water at national and global levels. Mining accounted for 4% of the water used in Canada in 2005, versus 60% for coal and nuclear electric power generation, 18.5% for manufacturing, 9.5% for municipal water supplies, and 8% for agriculture. Mining accounts for 1% of water used in the U.S., and 2-3% of the total water consumed in Australia.

The rate of water reuse and recycling in mineral processing is often very high at mine sites, especially in areas with arid climates. A number of innovative water conservation practices are being developed and implemented to reduce water use.

Types of mine water

There are a number of classifications of mine water, which can vary in their quality and potential for contamination:

- Mine water: refers to any surface or groundwater present at the mine site

- Mining water: water which has come into contact with any mine workings

- Mill water: water used to crush and grind ore, may contain dissolved minerals and/or metals

- Process water: water used in the chemical extraction of metals, commonly contains process chemicals

- Leachate: water which has trickled through solid mine wastes and may contain dissolved minerals, process chemicals, and/or metals

- Effluent: Mining, mill, or process water which is being discharged into surface water, often after being treated

- Mine drainage water: Surface or groundwater which flows or has the potential to flow off the mine site

Typically, all the mine water at metal mines is collected and stored in tailing ponds before being treated and released to surface water if necessary.

SERES Mine Water Online analysers

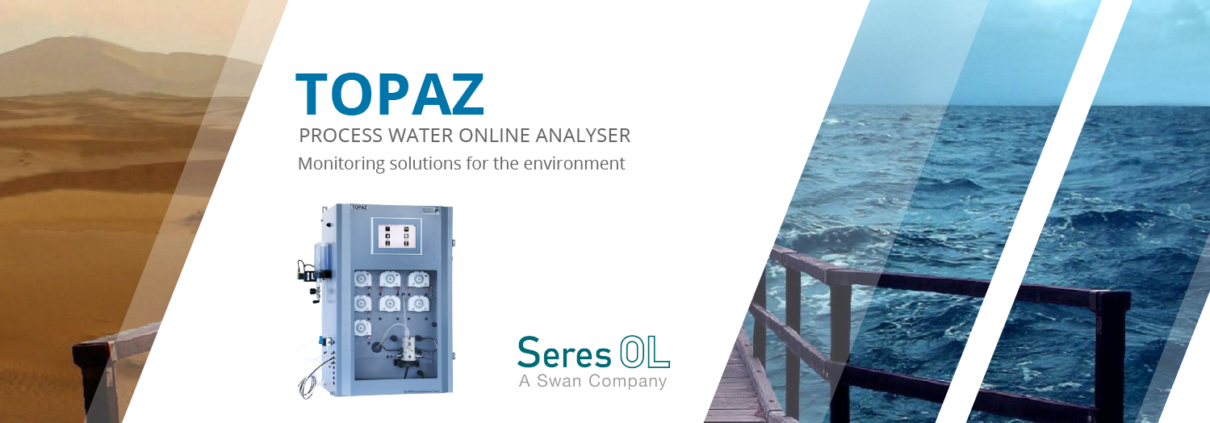

SERES large portfolio of on-line analysers enables you to monitor precisely the complete mining process, from influent to effluent. Compliance with discharge regulations is another application example and typically expressed as sum parameters, for which SERES has unique solution.

The TOPAZ mine water online analysers are designed for automatic and continuous monitoring of a several parameters amongst a large range of chemical compounds in all type of water. Thanks to its concept using a combination of analytical methods (Colorimetry, Titrimetry and Potentiometry or selected absorption) the TOPAZ allows accurate, reliable and versatile water quality monitoring. With multistream capabilities up to 6 channels, the TOPAZ fulfils the industrial requirements and demands of mine water analysis.

Some of the TOPAZ analysers suited to the mining industry

|

Specs vs Parameters |

Chrome

Total Chrome |

Lead | Manganese | Copper | Nickel |

| Sample preparation | Dilution required above

1000 µg/l Filtration if required |

Dilution required above

3 mg/l Filtration if required |

Dilution required above

2000 µg/l Filtration if required |

Dilution required above

5 mg/l Filtration if required |

Dilution required above

2 mg/l Filtration if required |

| Method | Colorimetry | Colorimetry | Colorimetry | Colorimetry | Colorimetry |

| Measuring range | 0-1000 µg/l | from 0-1 mg/l to 0-3 mg/l | from 0-200 µg/l to

0-2 mg/l |

0-5 mg/l | 0-2 mg/l |

| L.D.L

Lower Detection Limit |

10µg/l | 0.13 mg/l | 11 µg/l | 9 µg/l | 0.07mg/l |

| Accuracy | <1-2 % Full range | <1 % Full range | <3 % Full range | <3 % Full range | <3 % Full range |

| Repeatability | <1-2 % Full range | <1 % Full range | <2 % Full range | <3 % Full range | <2 % Full range |

| Response time | 10 min

40 min (CT) |

5 min | 15 min | 20 min | 15 min |

AT THE HEART OF INNOVATION

SERES environnement is continually implicated in the process of technological innovation. “We constantly re-invest in research and development in order to provide our clients with the most advanced technologies. For SERES, the notion of change is a permanent challenge. We work in partnership and collaboration with French and foreign research centres (such as the CNRS – the French National Centre for Scientific Research), Engineering Colleges and Universities.” SERES environnement makes 60% of its turnover on the export market in more than 35 countries with references in the Oil & Gas, Water treatment, Cement and Glass industry, Energy and large manufacturing companies…