Oxygen Analyser

Oxycheck™

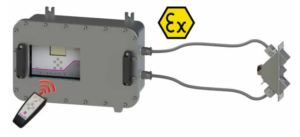

Oxycheck™ is Pillard’s last generation of insitu probe designed for fuel-efficiency in combustion and post combustion applications. Providing realtime, accurate and reliable Oxygen measurements, the Oxycheck™ enables safe and efficient operations and automations in small to large scale combustion plants such as boilers, industrial burners, power plants.

Smart Design

As a fixed insitu device, Pillard Oxycheck™ analyzer is designed to be mounted directly at industrial stacks, ducts or along exhaust lines. Pillard Oxycheck™ solution consists of a light weight and robust Oxycheck™ measuring probe and its associated electronics (control unit). For flexible installation and ease of operations, the Oxycheck™control unit can be located up to 10 m from the measuring probe. A signal lamp on the control unit keeps the operator informed immediately about the system status eliminating the need for regular site attendances and visual inspections.

Reliable operation and Certified for combustion control

The Oxycheck™ uses an interference-free and extremely sensitive method based on the integration of a Zr zirconium dioxide measuring cell fitted inside the tip the probe. While directly inserted in the flue gas stream, the Oxycheck™ Zr cell is sensing variations of the O2 content in the flue gas in less than a few seconds. Pillard Oxycheck™ complies with SIL2 certifications guaranteeing operational safety and improving energy performances in combustion plants.

Easy maintenance

The Oxycheck™ measuring probe concept simplifies the maintenance tasks by providing an easy access the sensor. With a minimum calibration interval of six months, the maintenance is very simple and quick and only consists in cleaning the sensor and replacing the filters.

Exclusive Features

Oxycheck™

Safe and efficient automations in combustion plants

|

Oxycheck™ 3-year warranty |

Certification SIL2, 61508 |

| Measuring range 0 to 20.9% | Response time less than 200 sec |

Specifications

Oxycheck™

Oxygen Analyser

Analytical Performances

Technology in situ probe / electrochemical sensor

Measuring range 0 to 20.9%

Accuracy 2% of full scale

Response time >200sec

Pleasant interface

Analogue Outputs

Three 4 – 20 mA on 300Ω max.

Output contacts

RT contact 250V-2A

Construction

Enclosure IP65 Ingress Protection

Certification EN60529

Weight From 8,4 to 12,6kg

External dimensions From 615mm to 2.365mm

Power supply 115Vac or 230Vac / 50Hz – 60Hz

Power Consumption 50VA

Options

Tailor made probe length

Remote control

Calibration Kit

Measured Parameters

Oxycheck™

The Oxycheck™ is a stable and accurate analysing probe for a real-time measure of oxygen concentration in combustion fuel gas and ensures fuel-efficiency of the industrial burner.

| PARAMETER | RANGE |

|---|---|

| Oxygen O2 | 0 to 20.9% |

INSITU Measuring Probe

Oxycheck™

Oxygen Monitoring Solution

Oxycheck™

Oxygen Analyser for fuel-efficiency in industrial burners

Industrial Stacks

Oxycheck™

With stricter environmental regulations optimisation of the combustion process for reduced pollutant emission and higher fuel efficiency is a major objective for manufacturers.

Monitoring solutions and applications for stack industries

- Oxygen concentration monitoring, in combustion flue gas to ensure safe and efficient operations and automations in small to large scale combustion plants such as boilers, industrial burners, power plants.

- Low dust concentration monitoring, to ensure continuous measure and control dust emissions to all stacks industries.

Industrial Burners

Oxycheck™

Flame monitoring and applications for industrial burners

Flame scanners are compatible with all types of fuels and can be used in the following industries:

- Energy

- Petrochemical

- Cement

- Steel

- Claus Unit

Proven technology for industrial burners flame monitoring and all types of fuels:

- Ultra-Violet radiation technology, which monitors flame presence of gas and diesel oil.

- Infra-red technology, which monitors heavy oil, coal, or liquid fuel.

- Pyrometric technology, which monitors the flame presence of acid gas and multi-fuel combustion.

Cases Studies

Oxycheck™

https://www.aquagas.com.au/wp-content/uploads/2024/06/AquaGas-Green-Tech1.png

681

908

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2024-06-04 22:07:182024-06-26 21:30:08Made to Measure

https://www.aquagas.com.au/wp-content/uploads/2024/06/AquaGas-Green-Tech1.png

681

908

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2024-06-04 22:07:182024-06-26 21:30:08Made to Measure https://www.aquagas.com.au/wp-content/uploads/2024/05/Anikair-Aquagas-Farms-scaled.jpg

1697

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2024-05-22 22:38:212024-05-22 22:42:43Advanced Environmental Monitoring for Farms

https://www.aquagas.com.au/wp-content/uploads/2024/05/Anikair-Aquagas-Farms-scaled.jpg

1697

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2024-05-22 22:38:212024-05-22 22:42:43Advanced Environmental Monitoring for Farms https://www.aquagas.com.au/wp-content/uploads/2022/12/Proceas-Durag-01.png

1398

2481

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2024-03-26 22:59:162024-04-08 20:29:19New ProCeas AIR ref in NSW

https://www.aquagas.com.au/wp-content/uploads/2022/12/Proceas-Durag-01.png

1398

2481

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2024-03-26 22:59:162024-04-08 20:29:19New ProCeas AIR ref in NSW https://www.aquagas.com.au/wp-content/uploads/2024/02/AquaGasAirqual1.png

295

706

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2024-02-15 17:52:212024-06-27 21:55:15Empower Your Safety with AIRQUAL-1

https://www.aquagas.com.au/wp-content/uploads/2024/02/AquaGasAirqual1.png

295

706

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2024-02-15 17:52:212024-06-27 21:55:15Empower Your Safety with AIRQUAL-1 https://www.aquagas.com.au/wp-content/uploads/2023/08/AquaGas-Peracetic-Acid.png

732

1097

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-08-19 22:57:512023-08-19 23:20:48Peracetic Acid Exposure Monitoring

https://www.aquagas.com.au/wp-content/uploads/2023/08/AquaGas-Peracetic-Acid.png

732

1097

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-08-19 22:57:512023-08-19 23:20:48Peracetic Acid Exposure Monitoring https://www.aquagas.com.au/wp-content/uploads/2023/08/AquaGas-Snowy-Mountains-project-scaled-e1691936503389.jpeg

1036

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-08-13 14:20:212023-11-09 12:32:49Two CEMS for a Power Station in NSW

https://www.aquagas.com.au/wp-content/uploads/2023/08/AquaGas-Snowy-Mountains-project-scaled-e1691936503389.jpeg

1036

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-08-13 14:20:212023-11-09 12:32:49Two CEMS for a Power Station in NSW https://www.aquagas.com.au/wp-content/uploads/2023/08/AquaGas-DadoLab-Post-Blog-scaled.jpeg

1440

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-08-05 17:39:432023-08-19 22:47:01Cutting-edge solutions for stack emission and environmental sampling

https://www.aquagas.com.au/wp-content/uploads/2023/08/AquaGas-DadoLab-Post-Blog-scaled.jpeg

1440

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-08-05 17:39:432023-08-19 22:47:01Cutting-edge solutions for stack emission and environmental sampling https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas-Chemical-Vapor-Monitoring.png

839

1258

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-29 14:46:042023-08-08 22:29:26Air Monitoring for Workplace Safety

https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas-Chemical-Vapor-Monitoring.png

839

1258

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-29 14:46:042023-08-08 22:29:26Air Monitoring for Workplace Safety https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas-Ellona-Paris-odour-control-crop.png

1143

2782

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-23 13:39:062023-08-19 22:47:16Smart sensors enhance odour control at Paris waste-to-energy plant

https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas-Ellona-Paris-odour-control-crop.png

1143

2782

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-23 13:39:062023-08-19 22:47:16Smart sensors enhance odour control at Paris waste-to-energy plant https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas_Tocadero-Toc_product.png

1812

2644

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-09 21:06:292023-08-19 22:47:29TOCADERO TOC, more accurate and reliable measurements

https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas_Tocadero-Toc_product.png

1812

2644

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-09 21:06:292023-08-19 22:47:29TOCADERO TOC, more accurate and reliable measurements https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas-Veolia-Post-scaled.jpg

1920

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-07 22:36:302023-08-19 21:35:51Supply of SmartCEMS for multiple projects in Australia and overseas

https://www.aquagas.com.au/wp-content/uploads/2023/07/AquaGas-Veolia-Post-scaled.jpg

1920

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-07-07 22:36:302023-08-19 21:35:51Supply of SmartCEMS for multiple projects in Australia and overseas https://www.aquagas.com.au/wp-content/uploads/2023/06/AquaGas-SO3-monitor-post.png

1763

5042

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-06-04 11:57:412023-11-30 21:28:15SO3 Monitoring System

https://www.aquagas.com.au/wp-content/uploads/2023/06/AquaGas-SO3-monitor-post.png

1763

5042

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-06-04 11:57:412023-11-30 21:28:15SO3 Monitoring System https://www.aquagas.com.au/wp-content/uploads/2023/04/Post-Tunnel-Sensors.png

630

1255

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-15 16:35:492023-12-12 23:08:55Introducing FIVES Pillard Tunnel Sensors

https://www.aquagas.com.au/wp-content/uploads/2023/04/Post-Tunnel-Sensors.png

630

1255

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-15 16:35:492023-12-12 23:08:55Introducing FIVES Pillard Tunnel Sensors https://www.aquagas.com.au/wp-content/uploads/2023/04/Post-CEMS.png

303

726

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 22:28:342023-11-15 23:58:11Continuous Emissions Monitoring Systems

https://www.aquagas.com.au/wp-content/uploads/2023/04/Post-CEMS.png

303

726

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 22:28:342023-11-15 23:58:11Continuous Emissions Monitoring Systems https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Blog-Sustainable-Packaging.png

1679

2510

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 22:26:302023-10-12 20:04:10Mobile CEMS for sustainable packaging

https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Blog-Sustainable-Packaging.png

1679

2510

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 22:26:302023-10-12 20:04:10Mobile CEMS for sustainable packaging https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Multi-Metal-Smelter3.png

630

1255

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 22:16:162023-05-19 09:12:23Multi-metal smelter partners with AquaGas

https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Multi-Metal-Smelter3.png

630

1255

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 22:16:162023-05-19 09:12:23Multi-metal smelter partners with AquaGas https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Blog-Fertilising-Plant.png

684

2510

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 21:53:552023-10-12 20:44:24AquaGas SmartCEMS at the largest fertilisers plant

https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Blog-Fertilising-Plant.png

684

2510

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-12 21:53:552023-10-12 20:44:24AquaGas SmartCEMS at the largest fertilisers plant https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Copper-facility.jpg

953

1429

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:54:122023-08-19 20:31:26NH3 AQMS in South Australia

https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Copper-facility.jpg

953

1429

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:54:122023-08-19 20:31:26NH3 AQMS in South Australia https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Copper-mine.jpg

882

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:39:112023-07-29 13:00:138 AQMS for a Copper Mine

https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Copper-mine.jpg

882

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:39:112023-07-29 13:00:138 AQMS for a Copper Mine https://www.aquagas.com.au/wp-content/uploads/2022/10/Screenshot-2022-10-03-at-23.35.03.png

769

1152

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:23:002023-07-29 12:53:59IAQ Sensors for Chemical Facilities in QLD

https://www.aquagas.com.au/wp-content/uploads/2022/10/Screenshot-2022-10-03-at-23.35.03.png

769

1152

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:23:002023-07-29 12:53:59IAQ Sensors for Chemical Facilities in QLD https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Offices-and-Warehouses-across-Australia-scaled.jpg

1440

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:13:532023-07-29 12:46:19Indoor air quality in offices and warehouses

https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Offices-and-Warehouses-across-Australia-scaled.jpg

1440

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 22:13:532023-07-29 12:46:19Indoor air quality in offices and warehouses https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Distributor.png

1340

2001

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 21:52:192023-07-29 12:26:11Ellona Distributor for Australia

https://www.aquagas.com.au/wp-content/uploads/2023/04/Aquagas-Ellona-Distributor.png

1340

2001

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2023-04-03 21:52:192023-07-29 12:26:11Ellona Distributor for Australia https://www.aquagas.com.au/wp-content/uploads/2022/12/GHG_contract.png

1080

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-18 19:31:092022-12-22 19:39:17Greenhouse Gases (GHG) Fugitive Emissions

https://www.aquagas.com.au/wp-content/uploads/2022/12/GHG_contract.png

1080

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-18 19:31:092022-12-22 19:39:17Greenhouse Gases (GHG) Fugitive Emissions https://www.aquagas.com.au/wp-content/uploads/2022/12/GH2_contract.png

1080

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-18 19:16:332023-03-13 22:23:16SmartCEMS® GH2 deployed @ multiple GH2 facilities across Australia

https://www.aquagas.com.au/wp-content/uploads/2022/12/GH2_contract.png

1080

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-18 19:16:332023-03-13 22:23:16SmartCEMS® GH2 deployed @ multiple GH2 facilities across Australia https://www.aquagas.com.au/wp-content/uploads/2022/12/UQ-1038x555-1.png

555

1038

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-16 00:18:192022-12-22 19:57:00SmartCEMS® GHG

https://www.aquagas.com.au/wp-content/uploads/2022/12/UQ-1038x555-1.png

555

1038

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-16 00:18:192022-12-22 19:57:00SmartCEMS® GHG https://www.aquagas.com.au/wp-content/uploads/2022/12/Aquagas-Thank-You.png

1080

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-15 23:34:242022-12-21 13:54:07A note of thanks

https://www.aquagas.com.au/wp-content/uploads/2022/12/Aquagas-Thank-You.png

1080

1920

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-15 23:34:242022-12-21 13:54:07A note of thanks https://www.aquagas.com.au/wp-content/uploads/2022/12/Aquagas-Happy-New-Year.png

1081

1921

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-15 22:34:272023-01-01 19:31:58Warmth, joy, and peace from our crew to yours!

https://www.aquagas.com.au/wp-content/uploads/2022/12/Aquagas-Happy-New-Year.png

1081

1921

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-12-15 22:34:272023-01-01 19:31:58Warmth, joy, and peace from our crew to yours! https://www.aquagas.com.au/wp-content/uploads/2022/11/GH2-Cycle-3_website.png

1763

4168

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-11-16 00:24:382022-12-21 13:54:53PROCEAS® in GH2 Plants

https://www.aquagas.com.au/wp-content/uploads/2022/11/GH2-Cycle-3_website.png

1763

4168

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-11-16 00:24:382022-12-21 13:54:53PROCEAS® in GH2 Plants https://www.aquagas.com.au/wp-content/uploads/2022/11/Banner-AquaGas-4-scaled.jpg

931

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-11-15 00:02:252022-12-22 19:55:11SmartCEMS® in GH2 Plants

https://www.aquagas.com.au/wp-content/uploads/2022/11/Banner-AquaGas-4-scaled.jpg

931

2560

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-11-15 00:02:252022-12-22 19:55:11SmartCEMS® in GH2 Plants https://www.aquagas.com.au/wp-content/uploads/2022/11/GH2-Cycle-3_website.png

1763

4168

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-11-14 23:03:572022-12-21 13:55:52GREEN HYDROGEN [GH2]

https://www.aquagas.com.au/wp-content/uploads/2022/11/GH2-Cycle-3_website.png

1763

4168

AquaGas

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

AquaGas2022-11-14 23:03:572022-12-21 13:55:52GREEN HYDROGEN [GH2]

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

0

0

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-11-03 07:11:482022-12-20 11:48:03AquaGas SmartCEMS® solution

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

0

0

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-11-03 07:11:482022-12-20 11:48:03AquaGas SmartCEMS® solution https://www.aquagas.com.au/wp-content/uploads/2018/04/Woehler_A-550_Industrial_INT-1.jpg

1334

1999

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 05:24:162022-12-15 22:26:41A 550 Industrial Handheld Analyser

https://www.aquagas.com.au/wp-content/uploads/2018/04/Woehler_A-550_Industrial_INT-1.jpg

1334

1999

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 05:24:162022-12-15 22:26:41A 550 Industrial Handheld Analyser https://www.aquagas.com.au/wp-content/uploads/2018/09/Stack-testing-AquaGas-Pty-Ltd.jpg

1035

2552

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 03:46:422022-10-05 22:19:06NOx Emissions Testing

https://www.aquagas.com.au/wp-content/uploads/2018/09/Stack-testing-AquaGas-Pty-Ltd.jpg

1035

2552

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 03:46:422022-10-05 22:19:06NOx Emissions Testing https://www.aquagas.com.au/wp-content/uploads/2018/09/Banner_Airqual.png

524

1500

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 03:13:282024-01-19 00:50:08Breathing Air Quality

https://www.aquagas.com.au/wp-content/uploads/2018/09/Banner_Airqual.png

524

1500

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 03:13:282024-01-19 00:50:08Breathing Air Quality https://www.aquagas.com.au/wp-content/uploads/2018/09/OPENPITATNIGHT.png

713

1600

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 02:23:232022-10-05 22:17:42Flammable and toxic Offgas

https://www.aquagas.com.au/wp-content/uploads/2018/09/OPENPITATNIGHT.png

713

1600

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-09-13 02:23:232022-10-05 22:17:42Flammable and toxic Offgas https://www.aquagas.com.au/wp-content/uploads/2018/08/GOLD-COAST-AUSTRALIA.jpg

736

1494

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-08-02 05:38:082022-10-05 22:52:20City Of Gold Coast

https://www.aquagas.com.au/wp-content/uploads/2018/08/GOLD-COAST-AUSTRALIA.jpg

736

1494

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-08-02 05:38:082022-10-05 22:52:20City Of Gold Coast https://www.aquagas.com.au/wp-content/uploads/2018/08/Clean-Air-AquaGas.jpg

1000

1920

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-08-02 04:57:012022-10-05 22:25:23Odour Control Systems

https://www.aquagas.com.au/wp-content/uploads/2018/08/Clean-Air-AquaGas.jpg

1000

1920

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-08-02 04:57:012022-10-05 22:25:23Odour Control Systems

https://www.aquagas.com.au/wp-content/uploads/2022/09/E3_site.png

524

1500

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-07-30 03:03:372022-12-15 22:30:20WT1 Fence Line Monitoring Solution

https://www.aquagas.com.au/wp-content/uploads/2022/09/E3_site.png

524

1500

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2018-07-30 03:03:372022-12-15 22:30:20WT1 Fence Line Monitoring Solution

https://www.aquagas.com.au/wp-content/uploads/2017/08/Biogas.jpg

674

1200

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2017-08-21 06:45:312024-05-24 18:57:59Biogas Monitoring

https://www.aquagas.com.au/wp-content/uploads/2017/08/Biogas.jpg

674

1200

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2017-08-21 06:45:312024-05-24 18:57:59Biogas Monitoring

https://www.aquagas.com.au/wp-content/uploads/2015/03/slide1.jpg

314

1300

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2017-04-12 03:45:312022-10-10 22:22:39More on AquaGas.com.au

https://www.aquagas.com.au/wp-content/uploads/2015/03/slide1.jpg

314

1300

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2017-04-12 03:45:312022-10-10 22:22:39More on AquaGas.com.au https://www.aquagas.com.au/wp-content/uploads/2017/04/sydney-AquaFID-CEMS.jpg

400

1200

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2017-04-12 03:25:292022-10-10 22:28:36AquaFID THC CEMS – Continuous Emissions Monitoring Systems

https://www.aquagas.com.au/wp-content/uploads/2017/04/sydney-AquaFID-CEMS.jpg

400

1200

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2017-04-12 03:25:292022-10-10 22:28:36AquaFID THC CEMS – Continuous Emissions Monitoring Systems

https://www.aquagas.com.au/wp-content/uploads/2016/05/1217512_shortfin-barracuda-le-nouveau-sous-marin-phare-de-dcns-web-tete-021878385540.jpg

533

1000

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2016-05-15 00:41:552023-03-06 22:16:26Indoor air quality

https://www.aquagas.com.au/wp-content/uploads/2016/05/1217512_shortfin-barracuda-le-nouveau-sous-marin-phare-de-dcns-web-tete-021878385540.jpg

533

1000

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2016-05-15 00:41:552023-03-06 22:16:26Indoor air quality

https://www.aquagas.com.au/wp-content/uploads/2015/12/Nickelhub__014_-scaled.jpg

1707

2560

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2016-01-14 11:04:022023-03-06 23:07:02Process monitoring in biogas plants

https://www.aquagas.com.au/wp-content/uploads/2015/12/Nickelhub__014_-scaled.jpg

1707

2560

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2016-01-14 11:04:022023-03-06 23:07:02Process monitoring in biogas plants https://www.aquagas.com.au/wp-content/uploads/2015/10/chemical_carousel.jpg

486

1296

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2015-10-20 10:22:412023-03-13 22:50:46Online analysis in the Chlorine industry

https://www.aquagas.com.au/wp-content/uploads/2015/10/chemical_carousel.jpg

486

1296

aymeric

https://www.aquagas.com.au/wp-content/uploads/2015/09/aquagas_logo_500px-300x120.jpg

aymeric2015-10-20 10:22:412023-03-13 22:50:46Online analysis in the Chlorine industry